I ended up buying two more tools for this. I could have "faked it" with one of the measurements, but I didn't have the right tools (specifically a lathe) to make the tool for the second measurement. So I popped for a 2-tool set from TransmissionPartsUSA.com. It was JT-1301 and included a "transmission overdrive shim & intermediate shaft spacer tool". You'll also need a dial caliper for this measurement. Here they are.

You could easily make these tools if you have access to a machine shop. I don't, I'm grumpy about that fact. But I guess I'll make do.

The shaft-looking tool (on the right) is for determining what size o the intermediate shaft end play spacer you need to use. It's the same diameter as the intermediate shaft and exactly 5.50" long. That's the important part.

The bar-looking tool is for determining what size overdrive piston thrust plate to use. You use this tool for the first measurement as well. You can fake this tool by using a rigid bar of an exact thickness. This bar is exactly .500" thick. The .500" thickness corresponds with the tables in the repair manual. So it's a little easier to use. Length isn't important as long as it spans across the overdrive housing surface.

I start by taking the shaft tool and inserting into the bore in the overdrive gear train.

Make sure it's seated all the way against the shoulder. It has a positive "stop" when it's seated. It sits right atop the splines at the planetary gear.

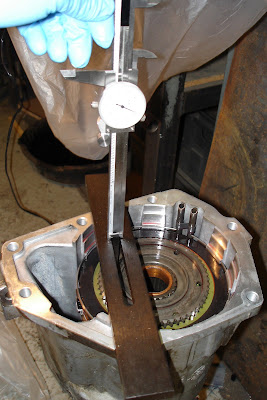

Now lay the bar across the mating surface of the overdrive housing.

Insert the end of your caliper into the slot in the bar and let it make contact with the end of the shaft tool.

There's a certain technique to this. I extended the caliper past what the measurement would be. Let the caliper end contact the shaft and then settle the caliper shoulders onto the bar. I made sure it was square, and then rocked the end of the caliper back a forth a little across the top of the shaft. This way, the measurement won't be greater than it's supposed to be. And it's near impossible to get a reading too small as well.

My reading came out as .746". According to my FSM (factory service manual) that means I need a spacer for the intermediate shaft that's .158" thick. There's a little chart in the manual for determining what size spacer to use.

End Play Measurement | Spacer Thickness | Transtar Part#

--------------------------------------------------------

.7336 - .7505 | .158 - .159 | 12708A

.7506 - .7675 | .175 - .176 | 12708B

.7676 - .7855 | .193 - .194 | 12708C

.7856 - .8011 | .211 - .212 | 12708D

BTW, I searched and searched to try and figure out what the "intermediate shaft end play spacer" was. None of the manuals showed it in the exploded diagrams. I only found it by searching through a parts catalog on the Transtar website. Transtar supplies almost all the rebuild parts to shops around the country. They don't sell retail! I didn't check with my online supplier, PATC, since I wanted the parts ASAP. I've had to develop a relationship with a local transmission builder, AAMCO of Brighton. They are willing to get the parts for me. I'm grateful for that.

This is where the intermediate shaft spacer sits. It's just to the left of the splines on the rear of the intermediate shaft in this photo. I totally missed it during the tear-down! Never saw it.

Now I'm ready to take the measurement for the overdrive piston thrust plate. This plate nests in the overdrive piston (we haven't talked about that yet) and pushes against the thrust bearing that sits atop the overdrive direct clutch hub.

Use the same bar used in the previous measurement. Now measure to the clutch hub thrust bearing seat (WITHOUT the bearing installed) in 4 different places 90* apart.

Average those measurements. (Add the four measurement up and divide by 4.) Then select the correct spacer from the chart.

My measurements where:

1.804"

1.806"

1.811"

+1.811"

-------

=7.323"

÷4

-------

=1.808"

From this measurement I determined that I need a spacer that's .153" thick.

Here's the chart:

End Play Measurement | Spacer Thickness | Transtar Part#

--------------------------------------------------------

1.7500 - 1.7649 | .108 - .110 |

1.7560 - 1.7799 | .123 - .125 |

1.7800 - 1.7949 | .138 - .140 | 12706A

1.7950 - 1.8099 | .153 - .155 | 12706B

1.8100 - 1.8249 | .168 - .170 | 12706C

1.8250 - 1.8399 | .183 - .185 | 12706D

1.8400 - 1.8549 | .198 - .200 | 12706E

1.8550 - 1.8699 | .213 - .215 | 12706F

1.8700 - 1.8849 | .228 - .230 | 12706G

1.8850 - 1.8999 | .243 - .245 | 12706H

Next: I get to move on to the main case! I'll start with the overdrive piston retainer.

5 comments:

Hello again. Iwas wondering if there was any way you could remeasure the "bar lookng tool" for me again and make sure it isn't supposed to be 5.050 instead of 5.50. Thanks.

I'll have to look when I get home, but I'm pretty sure its 5.5"

I'm going to make this tool. Did you find out that it is 5.5 rather than 5.05? Great write up, this is very helpful!!!

Am i to understand that the measurements you are using for the chart would include the thickness of the bar?

Awesome report. Would also like to know whats the real thickness.

Thank you

Post a Comment